When it comes to conveying, suction is an ideal method for keeping small, lightweight parts in place—but how does it work on a production line? Our vacuum conveyors consist of PureSteel® perforated metal belts, a vacuum box, or plenum, and a vacuum pump that pulls air down through those perforations. This creates a suction effect that will hold materials to the belt surface for maximum positioning control as they proceed along the track. In this blog, we’re examining the many benefits of vacuum conveyor systems and the applications that could be assisted by this technology.

When it comes to conveying, suction is an ideal method for keeping small, lightweight parts in place—but how does it work on a production line? Our vacuum conveyors consist of PureSteel® perforated metal belts, a vacuum box, or plenum, and a vacuum pump that pulls air down through those perforations. This creates a suction effect that will hold materials to the belt surface for maximum positioning control as they proceed along the track. In this blog, we’re examining the many benefits of vacuum conveyor systems and the applications that could be assisted by this technology.

The Precision Perforation Process

PureSteel® perforated metal belts are flat, endless metal conveyor belts manufactured with precision perforations. We use a variety of perforation methods based on the dimensions of the belt and the operational requirements of the vacuum conveyor system including:

- High-impact mechanical punching

- Chemical etching

- Laser cutting

Reaping the Benefits

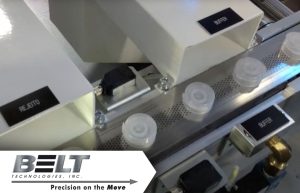

All of our vacuum systems provide accurate part positioning as well as smooth motion control and indexing. The primary benefit of these conveyors is to keep parts in place without requiring special clamping to hold the products, allowing for a smoother production. When combined with our perforated stainless steel endless metal conveyor belts, vacuum conveyor systems:

- Resist extreme high or low temperatures

- Offer corrosion resistance

- Are easy to maintain and clean

- Are clean and inert

- Do not generate particulate

Endless Applications

Suction is one of the best ways to keep small, flat and lightweight products “on track” in a conveyor system. The benefits of PureSteel® stainless steel vacuum conveyor belt systems make them a superior conveying method for a variety of industries and applications, including:

- Pick and place equipment

- Precision indexing

- Food processing

- Product assembly

- Pharmaceutical manufacturing

- Printing

- Clean room environments where no particulates are permitted

- Elevation changes

Coatings and surface treatments are also available for perforated metal conveyor belts. No matter your goal, our engineers will help you determine the right coating and PureSteel® product requirements for your system. Contact us to learn more about how we can put our vacuum conveyor solutions or any of our other custom solutions to work for you.