Friction drive pulleys are generally flat-faced with no timing element; crowning pulley faces are not generally recommended. To discuss the reasons why, please contact a Belt Technologies engineer who is familiar with metal belt dynamics. When crowning is appropriate, two geometries may be used: full radius and trapezoidal.

Full Radius Crown

A full radius crown is less stressful on the belt, but is more difficult to machine, and therefore, more costly.

Trapezoidal Crown

A trapezoidal crown is more cost effective, but it should be avoided in applications having high belt tensile loads due to stress risers at the crown’s transition points between angled flats. Blending these points can be helpful but does not eliminate the high-stress risers.

Other Considerations

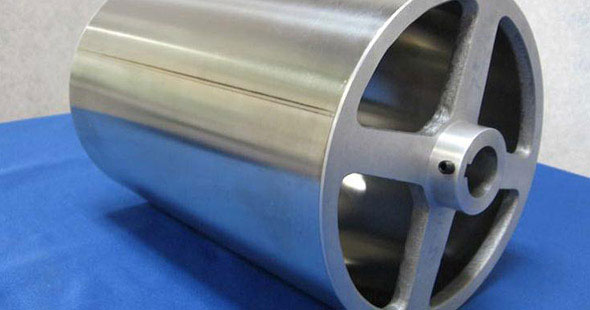

Friction drive pulleys can be designed as narrow-bodied rolls. Essentially, the narrow-bodied roll is a pulley with a width narrower than the belt running on it. They can make belt tracking easier and reduce total pulley weight and cost. The pulley face is typically no less than 1/2 the width of the belt.