Metal Belts Drive Productivity

Industrial automation solutions with engineering support

from concept to completion

Endless Metal Belts and Conveyor Systems are Durable, Clean and Accurate

Using sophisticated technology and innovative manufacturing processes, Belt Technologies, Inc. has been producing PureSteel® metal conveyor belts, metal timing belts and pulleys for automation applications and conveyor systems for over 50 years.

More durable, clean and accurate than fabric, rubber or PVC belts, PureSteel® metal belts from Belt Technologies benefit a wide range of industries, and work well in the most demanding production and quality control environments. Click here to learn about the features and benefits of PureSteel® metal belts or click on the images below to see how metal belts can help your facility.

Food manufacturing and processing

Great thermal conductivity and superior cleanliness for cooking and handling raw materials

Robotic automation

Smooth, reliable motion control with near zero backlash

Printing

Precise lateral and longitudinal positioning

Medical device manufacturing

Flawlessly sanitary, easy to clean and noncorrosive

Semiconductor manufacturing

Exceptional process control with maximum product yield in a cleanroom environment

Automated assembly lines

Material handling equipment operates with speed and precision

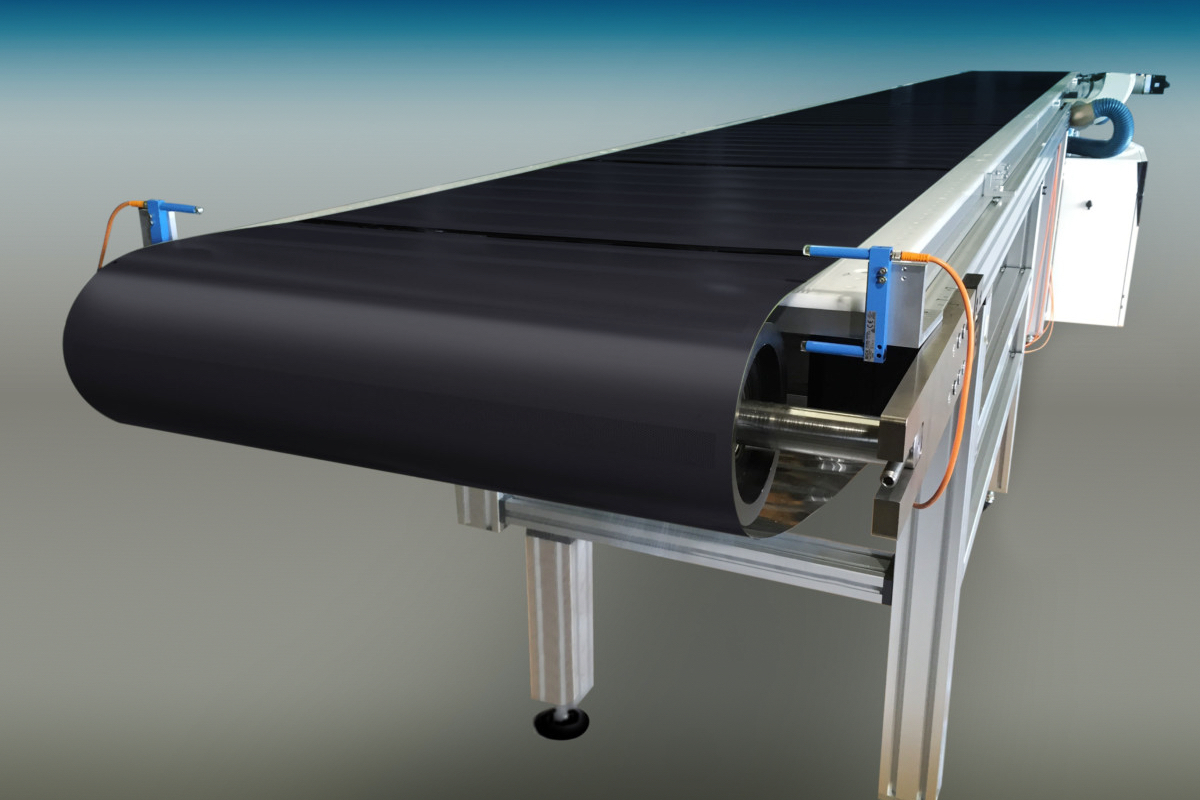

Conveyor Systems

Ready to upgrade your automation equipment?

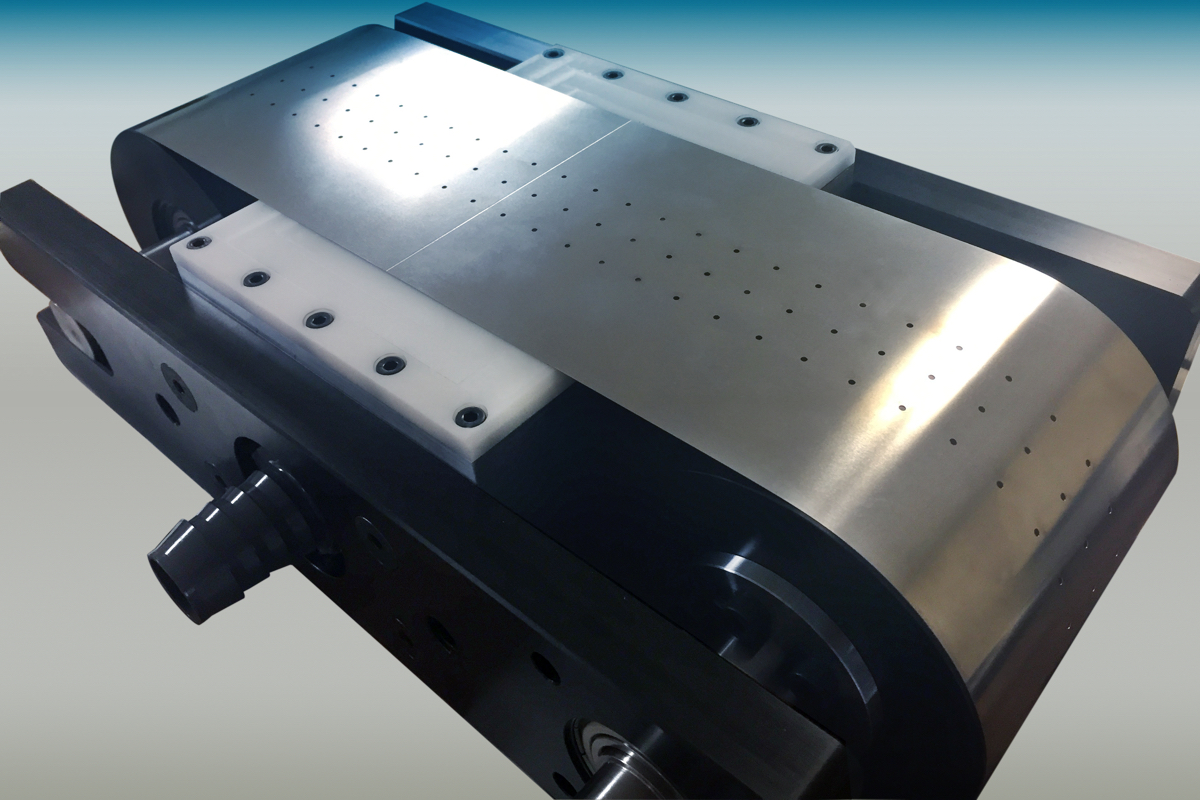

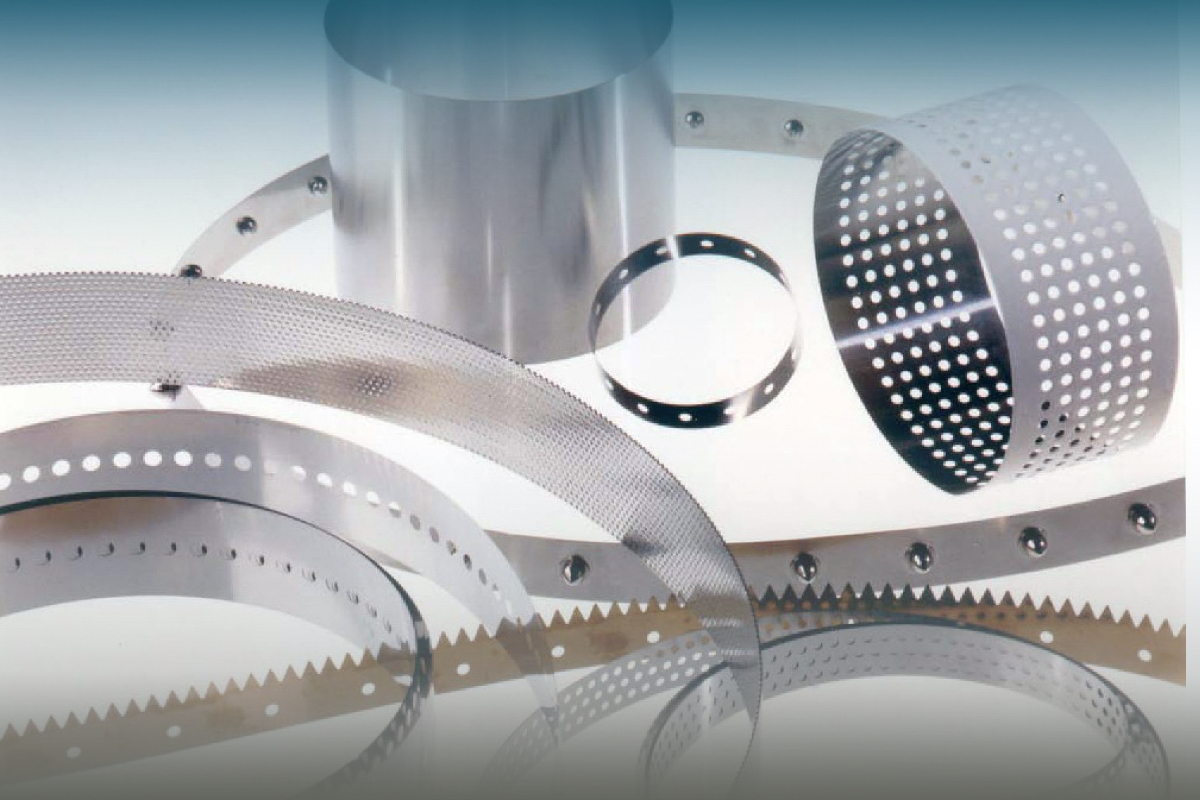

Endless Metal Belts and Drive Tapes

Endless Metal Belts and Drive Tapes

Resources for Engineers

In need of training materials or design guides?

Application-Specific Design and Manufacturing

Custom-designed, PureSteel® stainless steel metal belts and metal timing belts provide engineers with a wide range of manufacturing options due to their durability, flexibility and smooth operation. We will work with you to either convert existing automation equipment to a metal belt conveyor operation, or to design a new system to improve efficiencies and reduce operating costs.

Unique Properties and Capabilities of Metal Belts

Our PureSteel® metal belts are typically made of stainless steel to ensure longevity and durability under any conditions. Engineers may also choose from a variety of available alloys, which vary in resistance to chemicals, temperatures and corrosion. Belt material is selected based on the physical demands of the system, availability and cost.

Durable

Unlike polyester, nylon or cotton belts with rubber or plastic covers, PureSteel® metal belts can withstand temperature extremes, vacuum conditions and hostile, caustic environments. They are not susceptible to long-term wear and tear such as stretching or warping. Metal timing belts, metal conveyor belts and metal conveyor belt systems offer durability and strength while maintaining a lightweight flexibility for smooth, continuous operation.

Clean

PureSteel® metal belts do not generate component friction that would require lubrication, nor do they produce particulates or outgassing (as HTD or flat neoprene belts do). It is possible to sterilize them in an autoclave, making metal belts ideal for environments where cleanliness is paramount.

Accurate

PureSteel® metal belts do not exhibit pulsation, which is often seen in inferior belting materials. This enables precise transmission of the control system’s motion profile. Our metal belts are manufactured for smooth edges and precise dimensions with very tight tolerances to ensure the most accurate and reliable motion possible. We are able to fabricate metal belts with a station-to-station pitch accuracy of ±0.0005”.

What can metal belts do for your automation system?