Maintaining a high strength-to-weight ratio

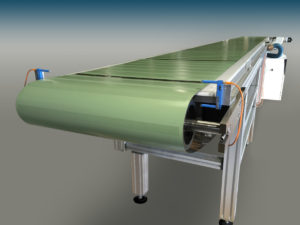

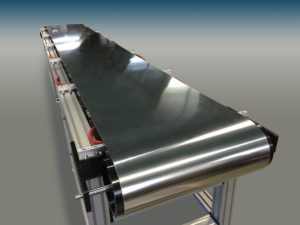

A wide metal belt on a Belt Technologies conveyor system demonstrates the versatility of metal belts that are both wide and extremely thin; the thin belt maintains a high strength-to-weight-ratio.

One of our core strengths that differentiates us from any other belt manufacturer is our unique ability to produce wide belts utilizing very thin material (typically 0.076–0.4 mm, or .003–.016”). Traditionally, wider belts are offered with material thicknesses of 1 mm or greater, which means working with pulley diameters in excess of 800 mm. The ability to use thinner materials creates significant space and cost savings and provides our customers with a potential competitive advantage over other machinery in medical, solar and many other industries.

Our customized, turnkey solutions meet even the most demanding, customer-specific processes and technical requirements. By using very thin materials, the complexity of belt tensioning and tracking devices is simplified. Customers who have made the switch from plastic, rubber or mesh belts to sanitary belts from Belt Technologies enjoy the following features and benefits:

Wide belts can be used with or without coating for food, medical, solar, and many other applications.

Decreased pulley diameter and increased space availability: Using thinner steel materials makes it possible to minimize the necessary pulley diameter, saving space with a decreased machine footprint. This is especially crucial with frozen foods and refrigerated areas.

Reduced inertia and increased cost savings: The smaller size also results in upfront cost savings to manufacture the drive system, as well as ongoing operating cost savings from lower replacement belt costs and less energy usage.

Improved heat transfer: By decreasing material thickness, we improve the heat transfer properties that solve thermal issues in many applications, such as the cooking of food products.

Decreased cleaning times and improved hygiene and cleanliness: Wide belts made of thin stainless steel can be cleaned and sanitized far faster than those made of plastic, rubber or mesh. These shortened cleaning times also lead to lower costs and improved environmental practices, reducing both water consumption and the need for detergents and cleaning agents.

Tracking devices can be used more effectively by using thinner material.

If you’d like to learn more about our PureSteel® sanitary stainless steel belts and the benefits that decreasing material thickness could bring to your facility, we hope you’ll contact us.