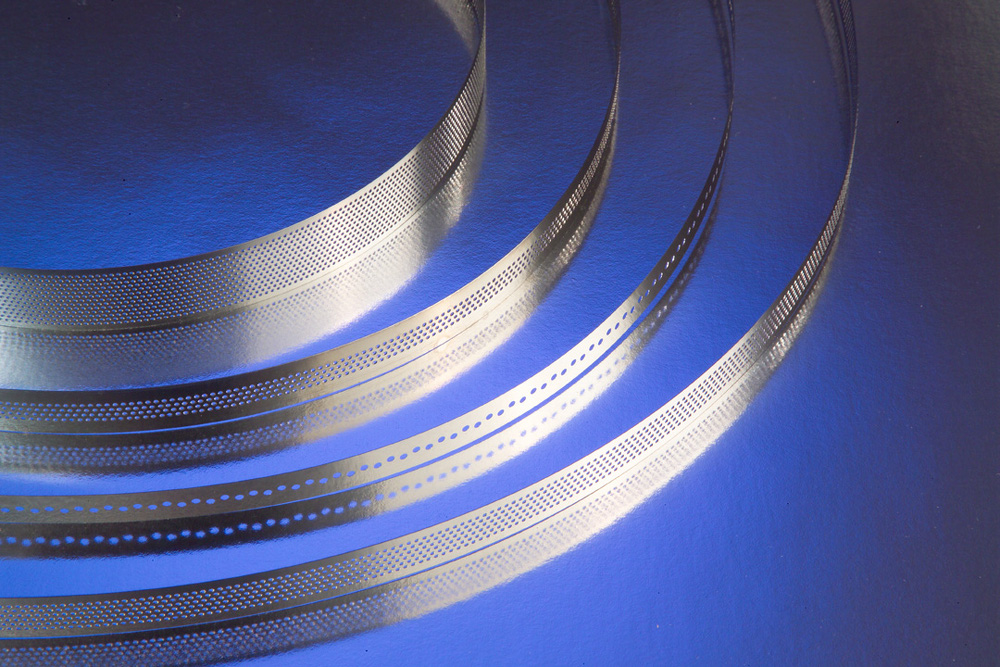

Perforated Belts

Belt Technologies has the capability to design and produce perforated metal conveyor belts using stainless steel with custom perforation patterns. We can apply the variety of available patterns through specialized perforation methods to guarantee the belt you order is the best match for your application.

Through careful and exact placement of the perforations along the length of the belt, we’re able to ensure the precise and accurate positioning of both the belt and products throughout their production process. Often leveraged by companies requiring precision indexing, perforated belts can be used in vacuum conveying and most any industry or company that is in need of secure transportation for the following applications:

- Solar panel production

- Printing presses

- Packaging

- Clean room environments

- Electronics manufacturing

- Pharmaceutical processing

- Medical device manufacturing

In addition to vacuum suction, perforated belts can be used in a variety of automated systems and automation tasks, including:

- Carriage positioning

- Indexing

- Timing

Perforation Methods and Techniques

A variety of methods can be used to create perforation patterns in PureSteel® stainless steel belts, such as stamping and laser cutting, and chemical etching. Some methods are more damaging to the structural integrity of the metal than others, but these challenges can often be overcome by consulting with our experienced sales engineers to determine optimal perforation patterns and methods in reference to your specific application.

Our in-house laser cutting services and perforation techniques produce consistent, accurate and precise perforations with no burr. We have the ability to perforate belts as thin as 0.002” (0.051 mm) or as thick as 0.031” (0.78 mm), and belts narrow as 0.125” (3.175 mm) or as wide as 36” (900 mm). We understand the many factors that must be considered when selecting a perforated metal conveyor belt to optimize its performance and durability. To ensure all technical aspects of your application are considered, contact our experts today.

Interested in learning more about perforated metal belts?