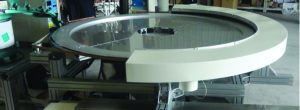

Steel strip used for rotary indexing tables

One of our long-standing customers, SFS Group Schweiz AG, offers cold forming automotive parts, and fasteners for the medical, construction and aviation industries.

Their precision-molded parts and mechanical fastening systems are embedded in their customers’ products, and while not always visible, fulfill mission-critical functions. When they needed a custom solution for one of their products, they counted on us to deliver.

The challenge

The SFS Group was looking for the right belt for a new rotary indexing table to transport coated screws through an oven. The screws are transported through a heat tunnel via magnets located in the rotary indexing table, which dries the liquid coating on the screws.

It was particularly important that the transport medium had magnetic permeability, while not being magnetic itself. It also had to be rust proof, corrosion resistant to certain chemicals and high-temperature resistant.

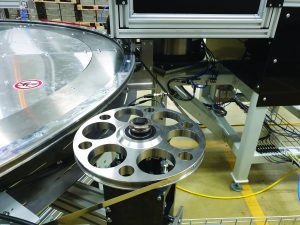

The steel belt separates the screws from the indexing table by passing over a small tension roller installed outside the indexing table. Therefore, the steel strip had to meet hardness and resistance thresholds so that it would not be damaged in this process.

The solution

We were able to successfully support SFS with our technical know-how in implementing the project. The endless steel belt we provided can withstand the temperature of the oven while allowing the magnetism in the table to penetrate the belt and hold the screws on the outer diameter of the belt.

It is also robust enough to be pulled off the table with a small pulley, so the screws fall off the table. If the belt was too thin, the screws being held by a magnet could cause damage to the belt.

The belt was implemented in the table’s design (similar applications exist) and is tensioned with the small roller. The majority of the belt is in contact with the rotating table.

The results were convincing and SFS will rely on us again for a second system being considered.

We can also support you in the implementation of your project. Contact our sales engineers at any time; they will be happy to provide you with advice and a custom solution.