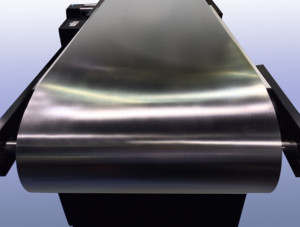

Our flat metal conveyor belts are made from a single sheet of high-end stainless steel.

Belt Technologies engineers have the knowledge and experience to not only design and build brand-new, custom conveyor systems, but also to retrofit existing conveyor systems to take advantage of the unique properties of stainless steel metal belts. When a customer contacts us with a problem regarding their existing systems, we are more than ready to examine their specific needs and provide a solution.

Product Manufacturing Requires Specialty Belts

A customer recently contacted Belt Technologies for a solution to a product-handling issue. They produced high-performance plastics and resins, which were being extruded onto a conveyor belt at high temperatures and allowed to cool as they were transported. The original conveyor belts were mesh metal belts; these were able to handle the high temperatures of the extruded plastic material but would leave markings on the plastic strands as the material cooled. The customer needed a new conveyor belt that could withstand elevated and varied temperatures without leaving any markings on the finished products.

Mesh or Flat Metal Belts: Which Do I Need?

The smooth finish of flat metal conveyor belts ensures there are no unwanted marks or dents on finished products.

Flat metal belts are durable and easy to clean. Their resistance to high heat makes them a great choice for applications using elevated temperatures. Unlike mesh metal belts, our flat metal conveyor belts are made from a single sheet of high-end stainless steel. Endless metal conveyor belts from Belt Technologies have a flat, even surface, which makes them ideal for applications that need a smooth product finish.

Mesh belts are another form of metal conveyor belt often used in high-heat applications. They are made of links, or metal weaves that allow the passage of fluids or air. While popular, the challenges and shortcomings of mesh belts can be detrimental to a production line. Hundreds or even thousands of links mean hundreds of difficult-to-clean recesses, making mesh belts a haven for contamination. Any misalignment of a mesh belt can result in damage to individual wires and links, making the risk for belt failure or damage to product significantly higher and increasing the potential for downtime. As demonstrated in this specific instance, the textured surface of a mesh belt can also result in damaged product that must be reworked or scrapped altogether. An upgrade to an endless, solid metal belt can eliminate many of the expensive risks associated with mesh belted conveyors.

Avoid Complete System Replacement with Affordable Retrofit Solutions from BTI

Belt engineers worked with the customer to design a new, flat metal conveyor belt that would easily integrate into the existing conveyor system. The new belt was made with 301 full hard-tempered stainless steel able to withstand the high temperatures required for the operation. The flat surface will not leave any marks on the extruded plastic as it cools.

With a retrofit solution from Belt Technologies, the customer was able to avoid the cost of replacing the entire system and can now achieve the smooth product results they needed. Is your existing conveyor system letting you down? Call or request a quote today and let our experts help find a solution!